By YOUSU 3D team | 17 November 2022 | 0 Comments

High Speed 3D printer-Raised 3d launched new generation high speed printing solution

High Speed 3d printer--Raised 3d launched new generation high speed 3d printing solution

Most of the speed of 3d printers be considered slow. However,with technology developing, we can see more and more high speed printers in both FDM and resin printing. For FDM 3d printers,the most famous ones brand are Delta 3d printer Flsun Super Racer, anker make M5. For resin 3d printer, Anycubic Photon M3 Plus&Max,Phrozen Sonic Mega 8K,Uniz Slash UDP,HP Jet Fusion 5200 etc.

On November 10, 2022, Raise3D announced a breakthrough in the field of FFF professional-grade 3D printing, and launched the Hyper Speed high-speed upgrade kit for Pro3 series 3D printers. Comprehensive technical innovation of hardware, slicer software and 3d printer filament to help users achieve fast and stable batch production.

Slow printing speed can only be a supplement to the traditional manufacturing process?

With the development of FFF/FDM 3D printing technology, prototyping, customization for special needs, and small batch production have also become easier and faster. But due to its slower printing speed and higher production costs, most people still think that FFF/FDM 3D printing is just a supplement to traditional manufacturing processes.

Raise3D has been deeply involved in FFF/FDM 3D printing technology, and has achieved breakthroughs in printing speed in recent years.

On the RMF500 released last year, we achieved an extrusion speed of over 350mm/s, an acceleration of 10,000 mm/s2, and a limit speed of 1m/s. Combined with IDEX independent dual nozzles, its printing efficiency will be 6-8 times as normal 3d printers.

Today, Raise3D has successfully applied the accelerated printing experience to the Pro3 series printers, achieving a speed 3.8 times faster than most professional-grade 3D printers on the market, breaking the bottleneck of FFF printing speed and redefining the productivity of FFF printing technology.

Feng Hua, founder and global CEO of Raise3D, said: "The results we have achieved in high speed printing are very significant, far more than our expectations, which gives us full confidence. We believe this will be a milestone in high-speed printing, not only for Raise3D, but also for the entire FFF/FDM-based 3D printing industry." He added: "Over the past few years, our technical advantage has been increasingly recognized. We're thrilled with the fact that the Hyper Speed upgrade kit has more than tripled the ROI for existing Pro3 users.

Active Vibration cancellation algorithm

The cornerstone of stable and high-speed production

When it comes to high-speed printing, the role of hardware is to ensure that the 3D printer can still have stable, high-precision print quality under high-speed printing.

The core of Hyper FFF™ technology is an active vibration cancellation algorithm. Whenever the printer head makes any high-speed directional changes, it calculates an optimized acceleration pattern and absorbs excess vibration. By measuring the frequency of the extruder nozzle, the processor divides the single acceleration command into two equivalent accelerations to generate two opposing vibrational waves that offset their vibrations in the reverse phase, so using the same hardware, the printer nozzle manages to reduce its own friction and vibration.

The sturdy and stable structure of the Raise3D Pro3 series can ensure that the printer still maintains high printing accuracy and excellent surface quality under extremely high acceleration and high-speed printing conditions. Additionally, the Pro3's advanced onboard processor allows our engineering team to unleash the power of innovative motion planning techniques. We are able to process over 600,000 steps per second, implementing an active vibration cancellation algorithm on the Pro3 series printers.

For Raise3D, the challenge of high-speed printing has never been more than just increasing the printing speed of 3D printers. Because it is not difficult to speed up a 3D printer alone, most manufacturers and DIY users have tried it. Ensuring the quality of high-speed printed parts is the goal we have been pursuing, and it is also the biggest challenge.

Therefore, the R&D team has carried out a comprehensive technical innovation to the entire Raise3D ecosystem, and launched specially designed Hyper Speed and Hyper Core series of filament for high-speed printing, as well as ideaMaker 4.4.0

Hyper Speed series filament are based on commonly used filament, such as PLA, ABS, PETG, PC, etc. At present, Hyper Speed PLA and Hyper Speed ABS have been launched. In the later stage, we will also gradually launch high-speed series of PETG, PC, ASA, anti-static and other filament.

Hyper Core high-speed series filaments are fiber-reinforced filament that can be used in heavy industry, including PPA CF, PA12 CF, etc., will be launched next year

High-speed and high-volume production with higher cost-effectiveness

One of the pilot users of Hyper FFF™ is a PCB manufacturer with over 2 million customers and 6 highly digitized manufacturing plants worldwide. They have established a Rapid Response Manufacturing Center with more than 100 manufacturing equipments, including 5 Raise3D Pro3 series printers. This pilot user purchased these Pro3 series printers to meet their customers’ needs of functional prototypes. For example, they once made an order for a set of PCB enclosures weighing 100-200 grams each, which was assembled from multiple parts, and the length of a single piece could reach 50 to 300 mm.

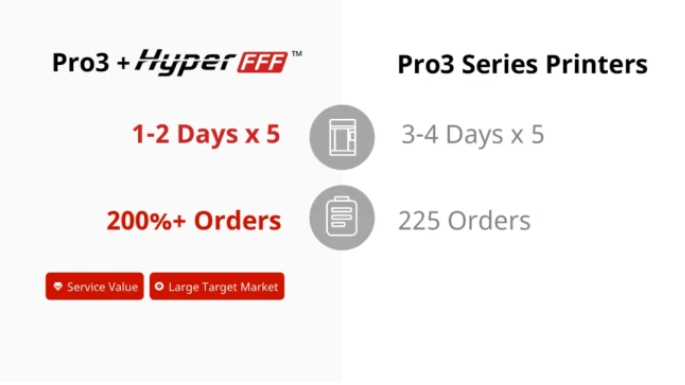

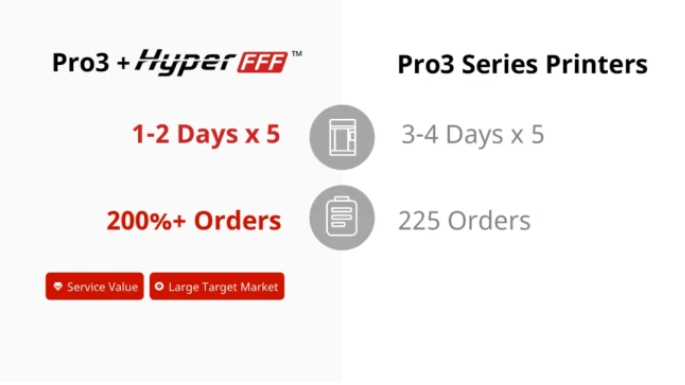

Before the Hyper FFF™ technology upgrade for the Pro3 series printers, the PCB manufacturer planned to process more than 200 orders per month, each requiring between 1 and 5 printed parts. This means that about 1,000 parts need to be printed each month, and in order to complete the order, five Pro3s need to be running 24 hours a day.

After a short trial period, the PCB manufacturer adjusted their business scenarios based on the new yields.

First, their average lead time has been shortened from 3-4 days to 1-2 days. As a result, the manufacturer has shortened their standard lead time so that more orders can be produced each month. In addition, manufacturers have the ability to produce urgent orders, especially urgent orders with bulk demand. In conclusion, the PCB manufacturer can fulfill more orders faster and expand their market share after using Hyper FFF™.

Hyper FFF™, just the first step

Future high-speed printing development plan

The success of the Hyper Speed high-speed upgrade kit (Pro3 series) has strengthened our confidence in high-speed printing. We are also continuing to develop and will gradually expand Hyper FFF™ to other product series, allowing more users to achieve "high-speed printing". high yield".

Most of the speed of 3d printers be considered slow. However,with technology developing, we can see more and more high speed printers in both FDM and resin printing. For FDM 3d printers,the most famous ones brand are Delta 3d printer Flsun Super Racer, anker make M5. For resin 3d printer, Anycubic Photon M3 Plus&Max,Phrozen Sonic Mega 8K,Uniz Slash UDP,HP Jet Fusion 5200 etc.

On November 10, 2022, Raise3D announced a breakthrough in the field of FFF professional-grade 3D printing, and launched the Hyper Speed high-speed upgrade kit for Pro3 series 3D printers. Comprehensive technical innovation of hardware, slicer software and 3d printer filament to help users achieve fast and stable batch production.

Slow printing speed can only be a supplement to the traditional manufacturing process?

With the development of FFF/FDM 3D printing technology, prototyping, customization for special needs, and small batch production have also become easier and faster. But due to its slower printing speed and higher production costs, most people still think that FFF/FDM 3D printing is just a supplement to traditional manufacturing processes.

Raise3D has been deeply involved in FFF/FDM 3D printing technology, and has achieved breakthroughs in printing speed in recent years.

On the RMF500 released last year, we achieved an extrusion speed of over 350mm/s, an acceleration of 10,000 mm/s2, and a limit speed of 1m/s. Combined with IDEX independent dual nozzles, its printing efficiency will be 6-8 times as normal 3d printers.

Today, Raise3D has successfully applied the accelerated printing experience to the Pro3 series printers, achieving a speed 3.8 times faster than most professional-grade 3D printers on the market, breaking the bottleneck of FFF printing speed and redefining the productivity of FFF printing technology.

Feng Hua, founder and global CEO of Raise3D, said: "The results we have achieved in high speed printing are very significant, far more than our expectations, which gives us full confidence. We believe this will be a milestone in high-speed printing, not only for Raise3D, but also for the entire FFF/FDM-based 3D printing industry." He added: "Over the past few years, our technical advantage has been increasingly recognized. We're thrilled with the fact that the Hyper Speed upgrade kit has more than tripled the ROI for existing Pro3 users.

Active Vibration cancellation algorithm

The cornerstone of stable and high-speed production

When it comes to high-speed printing, the role of hardware is to ensure that the 3D printer can still have stable, high-precision print quality under high-speed printing.

The core of Hyper FFF™ technology is an active vibration cancellation algorithm. Whenever the printer head makes any high-speed directional changes, it calculates an optimized acceleration pattern and absorbs excess vibration. By measuring the frequency of the extruder nozzle, the processor divides the single acceleration command into two equivalent accelerations to generate two opposing vibrational waves that offset their vibrations in the reverse phase, so using the same hardware, the printer nozzle manages to reduce its own friction and vibration.

The sturdy and stable structure of the Raise3D Pro3 series can ensure that the printer still maintains high printing accuracy and excellent surface quality under extremely high acceleration and high-speed printing conditions. Additionally, the Pro3's advanced onboard processor allows our engineering team to unleash the power of innovative motion planning techniques. We are able to process over 600,000 steps per second, implementing an active vibration cancellation algorithm on the Pro3 series printers.

For Raise3D, the challenge of high-speed printing has never been more than just increasing the printing speed of 3D printers. Because it is not difficult to speed up a 3D printer alone, most manufacturers and DIY users have tried it. Ensuring the quality of high-speed printed parts is the goal we have been pursuing, and it is also the biggest challenge.

Therefore, the R&D team has carried out a comprehensive technical innovation to the entire Raise3D ecosystem, and launched specially designed Hyper Speed and Hyper Core series of filament for high-speed printing, as well as ideaMaker 4.4.0

Hyper Speed series filament are based on commonly used filament, such as PLA, ABS, PETG, PC, etc. At present, Hyper Speed PLA and Hyper Speed ABS have been launched. In the later stage, we will also gradually launch high-speed series of PETG, PC, ASA, anti-static and other filament.

Hyper Core high-speed series filaments are fiber-reinforced filament that can be used in heavy industry, including PPA CF, PA12 CF, etc., will be launched next year

High-speed and high-volume production with higher cost-effectiveness

One of the pilot users of Hyper FFF™ is a PCB manufacturer with over 2 million customers and 6 highly digitized manufacturing plants worldwide. They have established a Rapid Response Manufacturing Center with more than 100 manufacturing equipments, including 5 Raise3D Pro3 series printers. This pilot user purchased these Pro3 series printers to meet their customers’ needs of functional prototypes. For example, they once made an order for a set of PCB enclosures weighing 100-200 grams each, which was assembled from multiple parts, and the length of a single piece could reach 50 to 300 mm.

Before the Hyper FFF™ technology upgrade for the Pro3 series printers, the PCB manufacturer planned to process more than 200 orders per month, each requiring between 1 and 5 printed parts. This means that about 1,000 parts need to be printed each month, and in order to complete the order, five Pro3s need to be running 24 hours a day.

After a short trial period, the PCB manufacturer adjusted their business scenarios based on the new yields.

First, their average lead time has been shortened from 3-4 days to 1-2 days. As a result, the manufacturer has shortened their standard lead time so that more orders can be produced each month. In addition, manufacturers have the ability to produce urgent orders, especially urgent orders with bulk demand. In conclusion, the PCB manufacturer can fulfill more orders faster and expand their market share after using Hyper FFF™.

Hyper FFF™, just the first step

Future high-speed printing development plan

The success of the Hyper Speed high-speed upgrade kit (Pro3 series) has strengthened our confidence in high-speed printing. We are also continuing to develop and will gradually expand Hyper FFF™ to other product series, allowing more users to achieve "high-speed printing". high yield".

Leave a Reply

Your email address will not be published.Required fields are marked. *